Engineering Design Eggert Pdf

Posted : admin On 24.10.2019Z8z.eBook Engineering Design Download PDF ePubYou can download this eBook for Free Here, download as a pdf, kindle, word, txt, ppt, rar and zip and save on your devices, Phone, or your notebook. Everybody will get much of knowledge by reading a book. The book actually willcontain certain things you need. Of course, you will get something based on the Engineering Design By Rudolph J. Eggert of the book itself.

This thorough and comprehensive book introduces topics in engineering design methods in a timely and orderly fashion and each new topic progressively builds on the. Engineering Design [Rudolph J. Eggert] on Amazon.com. *FREE* shipping on qualifying offers. Engineering Design is intended as a text for senior capstone courses as. ENGINEERING DESIGN EDUCATION: SURVEYS OF DEMAND AND SUPPLY. Specific engineering design topics and activities. (LeMaster, 2002: Eggert and Tennyson, 2000.

Reading online book will be great experience for you. It is usually cheaper that you mustbuy the book in the book store. Contain of the book is really same with the printed book. However, you have to be connected with internet and you can read the online book. One of online books that will be nice for you is book entitled Engineering Design By Rudolph J.

The online book is very nice with meaningful content. Writer of the Engineering Design By Rudolph J. Eggert is very smart in delivering message through the book.

Thereare some stories that are showed in the book. Reader can get many real examples that can be great knowledge. It will be wonderful. Easy, you simply Klick book download link on this page and you will be directed to the free registration form.

After the free registration you will be able to download the book in 4 format. PDFFormatted 8.5 x all pages,EPub Reformatted especially for book readers, Mobi For Kindle which was converted from the EPub file, Word, The original source document. Format it however you want! Do you search to download Engineering Design book? What will reader get after reading the online book Engineering Design By Rudolph J.

Actually, as a reader, you can get many lessons of life. It will be better if you read the book alone.

So, you can really feel content ofthe book deeply. From the lesson, you will know about the meaning of life and human around you. You will be smart in choosing the best option for your life.

Engineering Design Eggert Free Pdf

So, you will never do same mistakes again and again. It will be very importantfor you and other readers in the world.

So, human life will be harmonious and full of peace. To serve many readers to get the book entitled Engineering Design By Rudolph J. Eggert, this website is ready with easy way indownloading the online book. You can download the book by following easy steps that are suggested in the website. Actually, this website also provides other books with many kinds of genre.

So, by visiting of this website, people can getwhat they need and what they want. Engineering Design By Rudolph J. Eggert PDF Engineering Design By Rudolph J. Eggert Epub Engineering Design By Rudolph J. Eggert Ebook Engineering Design By Rudolph J. Eggert Rar Engineering Design By Rudolph J. Eggert Zip Engineering Design By Rudolph J.

Eggert Read Online.

This article needs additional citations for. Unsourced material may be challenged and removed. (September 2009) The engineering design process is a methodical series of steps that engineers use in creating functional products and processes. The process is highly - parts of the process often need to be repeated many times before another can be entered - though the part(s) that get iterated and the number of such cycles in any given project may vary. It is a process (often iterative) in which the basic sciences, mathematics, and engineering sciences are applied to convert resources optimally to meet a stated objective. Among the fundamental elements of the are the establishment of objectives and criteria, synthesis, analysis, construction, testing and evaluation. Contents.

Common Stages of the Engineering Design Process One framing of the engineering design process delineates the following stages: research, conceptualization, feasibility assessment, establishing design requirements, preliminary design, detailed design, production planning and tool design, and production. Others, noting that 'different authors (in both research literature and in textbooks) define different phases of the design process with varying activities occurring within them,' have suggested more simplified/generalized models - such as problem definition, conceptual design, preliminary design, detailed design, and design communication. A standard summary of the process in European engineering design literature is that of clarification of the task, conceptual design, embodiment design, detail design. In these examples, other key aspects - such as concept evaluation and prototyping - are subsets and/or extensions of one or more of the listed steps.

Engineering Design Rudolph Eggert Pdf

It's also important to understand that in these as well as other articulations of the process, different terminology employed may have varying degrees of overlap, which affects what steps get stated explicitly or deemed 'high level' versus subordinate in any given model. Research Various stages of the design process (and even earlier) can involve a significant amount of time spent on locating information and. Consideration should be given to the existing applicable literature, problems and successes associated with existing solutions, costs, and marketplace needs.

The source of information should be relevant, including existing solutions. Can be an effective technique if other solutions are available on the market. Other sources of information include the Internet, local, available government documents, personal organizations, vendor catalogs and individual available. Design requirements Establishing design and conducting, sometimes termed problem definition (or deemed a related activity), is one of the most important elements in the design process, and this task is often performed at the same time as a feasibility analysis. The design requirements control the design of the product or process being developed, throughout the engineering design process. These include basic things like the functions, attributes, and - determined after assessing user needs. Some design requirements include hardware and software parameters, and.

Feasibility In some cases, a is carried out after which schedules, resource plans and estimates for the next phase are developed. The feasibility study is an evaluation and analysis of the potential of a proposed project to support the process of.

It outlines and analyses alternatives or methods of achieving the desired outcome. The feasibility study helps to narrow the scope of the project to identify the best scenario. A feasibility report is generated following which Post Feasibility Review is performed. The purpose of a feasibility assessment is to determine whether the engineer's project can proceed into the. This is based on two criteria: the project needs to be based on an achievable idea, and it needs to be within. It is important to have engineers with experience and good judgment to be involved in this portion of the feasibility study. Conceptualization A concept study (, ) is often a phase of project planning that includes producing ideas and taking into account the pros and cons of implementing those ideas.

This stage of a project is done to minimize the likelihood of error, manage costs, and evaluate the potential success of the intended project. In any event, once an engineering issue or problem is defined, potential solutions must be identified. These solutions can be found by using, the mental process by which ideas are generated. In fact, this step is often termed Ideation or 'Concept Generation.' The following are widely used techniques:.

trigger word - a word or phrase associated with the issue at hand is stated, and subsequent words and phrases are evoked. independent design characteristics are listed in a chart, and different engineering solutions are proposed for each solution. Normally, a preliminary sketch and short report accompany the morphological chart. the engineer imagines him or herself as the item and asks, 'What would I do if I were the system?' This unconventional method of thinking may find a solution to the problem at hand.

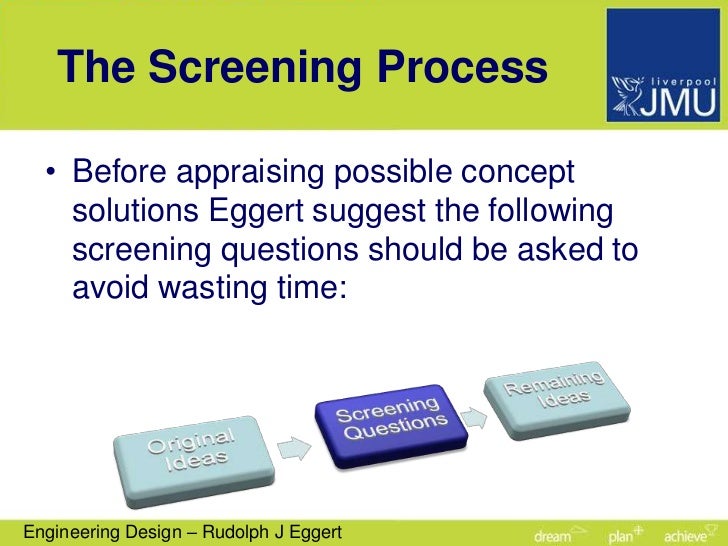

The vital aspects of the conceptualization step is synthesis. Synthesis is the process of taking the element of the concept and arranging them in the proper way. Synthesis creative process is present in every design. this popular method involves thinking of different ideas, typically as part of a small group, and adopting these ideas in some form as a solution to the problem Various generated ideas must then undergo a concept evaluation step, which utilizes various tools to compare and contrast the relative strengths and weakness of possible alternatives. Preliminary design The preliminary design, or high-level design includes (also called ), often bridges a gap between design conception and detailed design, particularly in cases where the level of conceptualization achieved during ideation is not sufficient for full evaluation. So in this task, the overall system configuration is defined, and, and of the project may provide early project configuration.

(This notably varies a lot by field, industry, and product.) During detailed design and optimization, the parameters of the part being created will change, but the preliminary design focuses on creating the general framework to build the project on. Blanchard and J. Fabrycky describe it as: “The ‘whats’ initiating conceptual design produce ‘hows’ from the conceptual design evaluation effort applied to feasible conceptual design concepts. Next, the ‘hows’ are taken into preliminary design through the means of allocated requirements.

There they become ‘whats’ and drive preliminary design to address ‘hows’ at this lower level.” Detailed design Following FEED is the Detailed Design (Detailed Engineering) phase, which may consist of of materials as well. This phase further elaborates each aspect of the project/product by complete description through, as well as. Design for manufacturability (DFM) is the general engineering art of designing products in such a way that they are easy to manufacture.

Operating parameters. Operating and nonoperating environmental stimuli. Test requirements. External dimensions. Maintenance and testability provisions. Materials requirements.

requirements. External surface treatment. Design life. requirements. External marking (CAD) programs have made detailed design phase more efficient. For example, a CAD program can provide to reduce volume without hindering a part's quality. It can also calculate and using the to determine stresses throughout the part.

Production planning The and tool design consists of planning how to the product and which tools should be used in the process. Tasks to complete in this step include selecting materials, selection of the production processes, determination of the sequence of operations, and selection of tools such as jigs, fixtures, metal cutting and metal or plastics forming tools. This task also involves additional iterations to ensure the mass-produced version meets standards. Comparison with the Scientific Method The engineering design process bears some similarity to the.

Both processes begin with existing knowledge, and gradually become more specific in the search for knowledge (in the case of 'pure' or basic science) or a solution (in the case of 'applied' science, such as engineering). The key difference between the engineering process and the scientific process is that the engineering process focuses on, and while the scientific process emphasizes. See also. (APDL).

References. ^ Ertas, A. The Engineering Design Process. New York, N.Y., John Wiley & Sons, Inc.

Engineering Design. New York, N.Y., John Wiley & Sons, Inc.

Engineering Design: a systematic approach. London, UK, The Design Council. ^ A.Eide, R.Jenison, L.Mashaw, L.Northup.

Engineering: Fundamentals and Problem Solving. New York City: McGraw-Hill Companies Inc.,2002. Ralph, P., and Wand, Y. A Proposal for a Formal Definition of the Design Concept. In, Lyytinen, K., Loucopoulos, P., and Robinson, W., (eds.), Design Requirements Engineering: A Ten-Year Perspective: Springer-Verlag, 2009, pp. (1997, April 9).

Introduction to finite element analysis. Retrieved from.

Archived from on 2011-05-14. Retrieved 2010-11-23. Dieter, George; Schmidt, Linda (2007). Engineering Design. Ullman, David G. (2009) The Mechanical Design Process, Mc Graw Hill, 4th edition,.

Eggert, Rudolph J. (2010) Engineering Design, Second Edition, High Peak Press, Meridian, Idaho.